- Via Alessandro Volta 62B 21010 Cardano al Campo (VA)

- info@thermogel.it

- +39 0331 1835350

The experience acquired in 50 years and the countless tests applied to each single product and in different production realities, have allowed us to design. High professional blast freezing, adapted to every specific need.

Particular attention is dedicated to the speed of reaching the temperature -18°C in the core, respecting the relative humidity values.

The productivity of our machines is expressed per kg / h, unlike the freezers proposed in the catering and gastronomy sector which indicate it for cycles ranging from 2 to 3 hours.

Our blast freezers perform 3 different functions:

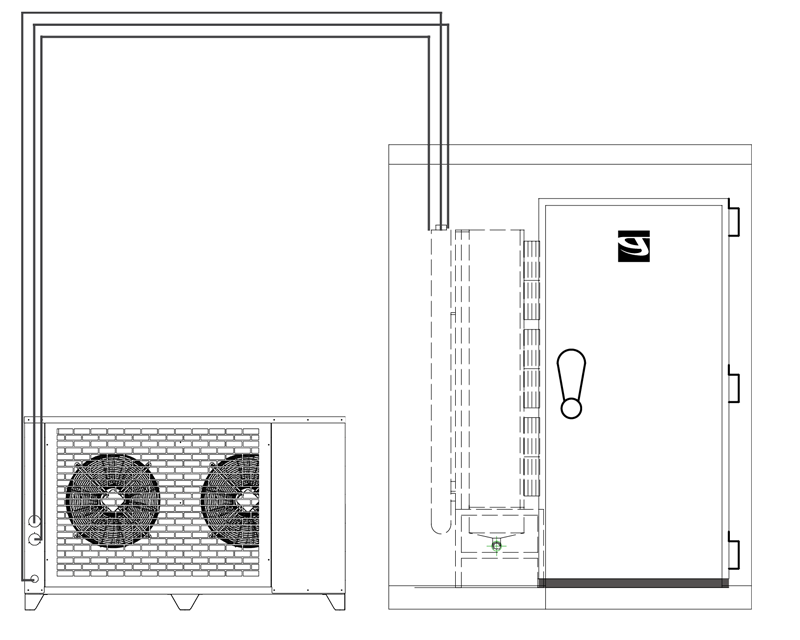

QF -40°C | -35°C

WALL MOUNTED EVAPORATOR

Thanks to an air temperature of -40°C, QF blast freezer lowers the temperature at the core of the food to -18°C in 60 min, a sufficient time to obtain micro-crystallization, keeping all the qualities of the food whole.

QT -38°C | – 20°C

CEILING EVAPORATOR

QT series is projected for a blast freezing obtained by in- direct air flow and permit the storing at wpml_nbsp -20°C for longer time than QF series.

The long experience at the side of pastry and bakery professional contributed to the realization of projects based on real and concrete production needs.

Each request and every project is realized considering the type of product, the quantities and the organization of the customer.

Our technical office studies different projects guaranteeing in every circumstance the required targets, in total respect of the final product quality. We also consider the logistical and environmental conditions where the machines have to work.

PRODUCT :

TARGET :

EXTERNAL CONDITIONS :

SOLUTION :

Our blast chiller and shock freezer warranty the best benefits in your work becoming the best partner for business.

Here some reasons:

1. HIGH PERFORMANCE

Work in continuous for all day manteining the same performace in every conditions and during the high production.

2. LESS DEFROSTING

Less defrosting steps ( every 8 hour ) and defrosting time is of 10-15 min.

3. SAVING TIME

High performance and efficent defrost lead to buy a lot of productive time

4. INCREASE PRODUCTIVITY

High performance and saving time are the key to obtain a sensible increase in productivity

5. ENERGY SAVING

The harmony between every technical elements, the right balance between Kw power <wpml_nbsp> and air distribution reduces the electrical consumption up to 20%

6. SAVING SPACE

Many time the space conditions the laboratory preventing a good organization.

Our machines are projected to minimize the encumbrances without compromising performance.

7. PRESERVE THE QUALITY

The most important benefit for us remain the certain respect of the original quality of the product.

8. ENJOY THE BENEFITS

More money for you and business higher.

More possibility to invest in your activity.